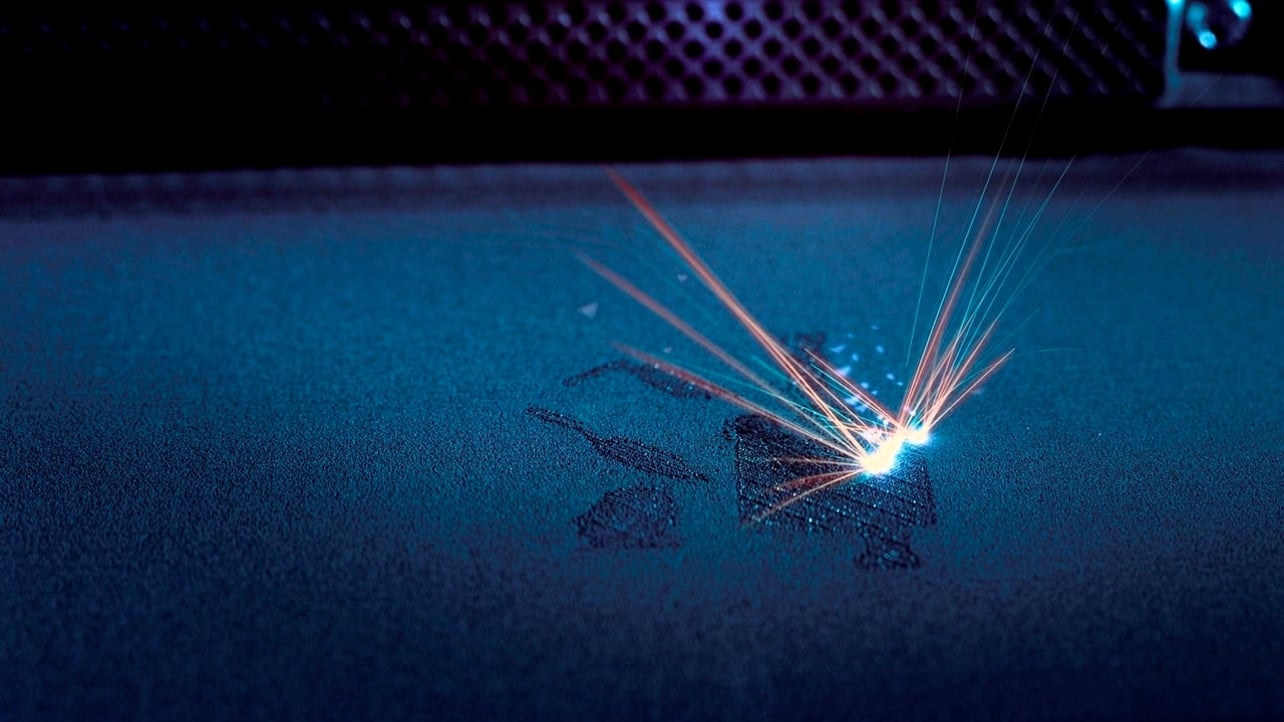

Selective laser sintering sls is a way to build prototypes early in the design cycle or production parts in a wide variety of applications.

Direct metal laser sintering machine cost.

With international certification standards iso 9001 and as9100 we have stringent systems in place to guarantee quality and consistently are met.

Selective laser sintering sls also just known as laser sintering ls creates tough and geometrically complex components for batch or serial manufacturing in a wide variety of applications.

Dmls direct metal laser sintering is an additive manufacturing method.

Direct metal laser sintering quality controls to maintain critical quality control standards we use a range of tools to inspect and ensure customer specifications.

The parts are built up additively layer by layer.

The eosint m 280 is the newest dmls machine from eos.

Tool less production with laser sintering makes it possible to manufacture different products one next to the other in one single process.

Like in the sls process your metal part will be created layer by layer according to your 3d model.

Direct metal laser sintering overview dmls is an additive manufacturing process used to create metal parts with complex geometries that are difficult to cnc machine.

The two are instantiations of the same concept.

A direct metal laser sintering dmls 3d printing machine is capable of producing highly complex features and all in one assemblies using metal materials that would be hard to achieve with more traditional subtractive manufacturing techniques such as cnc milling or turning.

To many slm is considered to be a subcategory of selective laser sintering.

Direct metal costs dmls materials direct metal laser sintering tim ruffner yeah i m so not making that up lol eos m270 gpi prototype instead of talking about myself or gpi prototype i have decided to share with you some costs and materials using direct metal laser sintertering aka dmls dmls.

The eosint m 270 builds metal parts using direct metal laser sintering dmls.

It creates parts additively by sintering fine metal powder particles to fuse them together locally.

Even highly complex geometries can be created directly from 3d cad data fully automatically in just a few hours.

A major difference is the sintering temperature.

Selective laser melting slm also known as direct metal laser melting dmlm or laser powder bed fusion lpbf is a rapid prototyping 3d printing or additive manufacturing technique designed to use a high power density laser to melt and fuse metallic powders together.

This makes laser sintering a viable manufacturing alternative.

How direct metal laser sintering works.