The choice of technology and deposition parameters allow for a wide variety of performance characteristics including hydrogenated and non hydrogenated dlc coatings.

Diamond like carbon coating process.

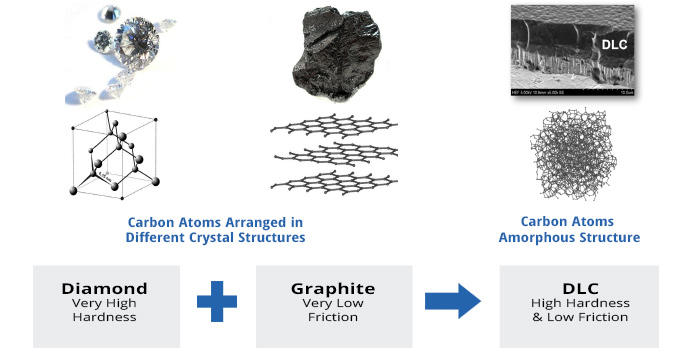

All seven contain significant amounts of sp 3 hybridized carbon atoms.

Diamond like carbon dlc pvd coatings diamond like carbon dlc coatings are a particular area of expertise for richter precision inc.

Diamond like carbon dlc coatings can be deposited by different technologies such as pvd arc pvd sputtering and pacvd processes.

Dlc exists in seven different forms.

Calico diamond like carbon dlc is a dense metastable form of hydrogenated amorphous carbon a c h containing significant sp3 bonding.

Dense smooth a c h dlc diamond like carbon coating.

During the dlc coating phase of the process a carbon carrying gas is introduced into the chamber.

This gas is the source for the amorphous carbon dlc coating.

This process of bonding carbon and hydrogen confers valuable diamond like properties such as mechanical hardness low friction optical transparency and chemical inertness.

Among pvd pacvd coating compositions and technology dlc coatings stand out as a distinctive category.

Dlc coatings can be amorphous more or less flexible hard strong and slick according to the composition and processing method.

If no underlayer is required a dense uniform coating of dlc can be deposited directly to the substrate as well.